IATF 16949 Internal Audit

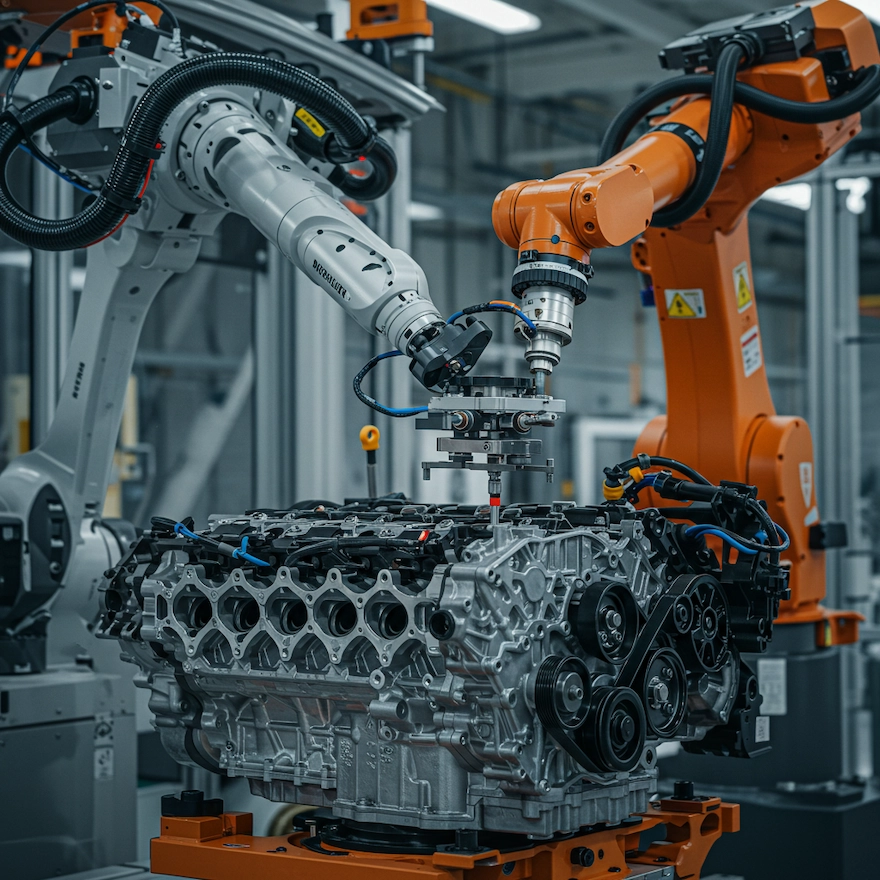

Master automotive QMS compliance with our premier IATF 16949 Internal Audit training in Malaysia. Learn risk-based auditing to verify quality system effectiveness and ensure process conformity. Conduct manufacturing process, product, and system audits for defect prevention assurance and customer requirements fulfillment. This program prepares you for third-party certification and automotive supply chain quality, covering core tools auditing and audit cycle management.

Focus of IATF 16949 Internal Audit Training: Expert Automotive Quality Auditing in Malaysia

Master risk-based audits and manufacturing process effectiveness.

Our Mission & Vision

Provide effective training and solutions that grow competitiveness of our clients.

Highlights of IATF 16949 Internal Audit Training: Expert Automotive Quality Auditing in Malaysia

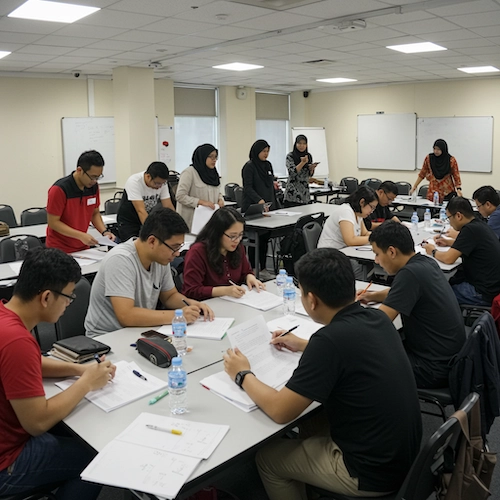

Master automotive audits, optimize efficiency, and gain practical case experience.

This program uniquely balances theory with intense practice. Learn from seasoned experts with deep automotive process auditing expertise. Through hands-on automotive case studies and mock process audits, you gain practical skills to optimize audit program efficiency and drive process performance improvement. Move beyond theory to achieve immediate manufacturing efficiency enhancement and operational compliance optimization.

Master IATF 16949 auditing with practical automotive case studies and hands-on exercises to optimize your audit program and enhance manufacturing efficiency. Book now!

Frequently Asked Questions: 3C

FAQ 1. What COMPETENCY and skills will I gain from this training?

FAQ 2. Can the training be tailored or CUSTOMISED to our organizations specific needs?

FAQ 3. Will I receive a recognized qualification or CERTIFICATE?

Competency

Customization

Certificate

Master risk-based automotive process audits effectively.

This training develops expert internal auditors to master risk-based audits, verify process effectiveness, and ensure compliance with IATF 16949 and customer-specific requirements for sustained quality.